Power factor is one of those electrical terms that sounds like it belongs in a switchboard room, until it starts quietly inflating your energy bills, stressing equipment and triggering avoidable network demand issues.

If you operate a commercial building, industrial facility, data centre or a site with lots of motors, drives and mechanical plant, power factor is not just an academic metric. It’s a practical indicator of how efficiently your site is using electrical power.

What Is Power Factor?

At a basic level, it describes how effectively electrical power is being converted into useful work. In AC systems, not all the power drawn from the network does something productive at the load.

There are two key components. Real power (kW) is the power that does useful work – turning motors, heating elements, running compressors and lighting spaces. Reactive power (kVAr) is power that’s required to magnetise equipment like motors and transformers but doesn’t produce useful work on its own.

Power factor is the relationship between real power (kW) and apparent power (kVA). It’s usually expressed as a number between 0 and 1 or as a percentage. A reading of 1.0 (or 100%) means nearly all supplied power is doing useful work. A lower reading means more current is required to deliver the same kW to your equipment.

That extra current is where the headaches begin.

Why Poor Power Factor Happens

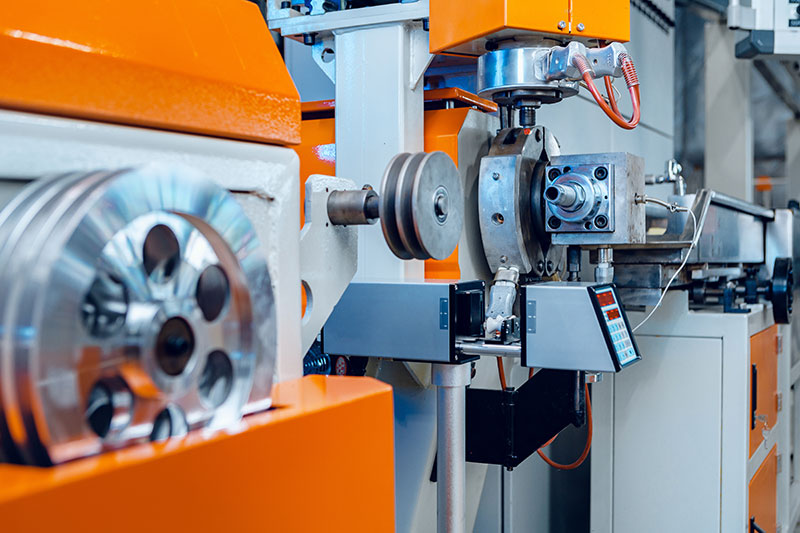

Poor power factor is most commonly associated with inductive loads, equipment that relies on magnetic fields. In many facilities, that describes a big chunk of the electrical load profile. Typical culprits include induction motors (fans, pumps, compressors, conveyors), transformers (especially when lightly loaded), HVAC systems and chilled water plants, older fluorescent lighting with magnetic ballasts and welders and certain industrial machinery.

As a rule of thumb, a site with heavy motor loads, particularly those running at partial load, will often see power factor drift down. There’s another twist that’s increasingly relevant: harmonics. Modern buildings and industrial sites use a lot of power electronics such as variable speed drives, UPS systems, LED drivers and switch-mode power supplies. These create non-linear loads that distort current waveforms.

In that scenario you might have a decent “displacement” power factor (phase shift) but a poor “true” power factor due to distortion. The end result can still be higher currents and higher losses, even if your main switchboard meter shows something that looks acceptable.

What Poor Power Factor Costs You

The impact of shows up in a few places, some obvious, some hidden.

Higher Electrical Losses and Heating

Lower power factor generally means higher current for the same useful kW. Higher current increases I²R losses in cables, busbars and transformers. That extra heat can shorten equipment life and reduce overall system efficiency.

Reduced Capacity of Your Electrical Infrastructure

Switchboards, transformers and cables are sized in kVA and current. When power factor is low, you “use up” capacity without gaining useful output. That can limit expansion, force upgrades earlier than planned or contribute to nuisance tripping and voltage drop.

Potential Utility Penalties or Demand Impacts

Many electricity retailers and networks encourage (or require) sites to maintain acceptable levels. Where penalties apply, they’re often tied to reactive energy consumption or kVAr demand. Even when there isn’t a direct penalty line item, poor readings can influence maximum demand behaviour and overall network efficiency at the site.

Poor Power Quality Symptoms

Low power factor can sit alongside broader power quality issues, voltage regulation challenges, harmonic distortion and stressed capacitors or transformers. If you’ve ever seen unexplained overheating, transformer hum, capacitor failures or erratic drive behaviour, it’s a sign your site needs better visibility into what’s really happening.

What "Good" Power Factor Looks Like

Many commercial and industrial sites aim for 0.9 to 0.95 or higher, depending on tariffs, network requirements and load type but it’s not just about hitting a single number. The best target depends on your load profile (steady versus variable), motor loading levels, presence of variable speed drives and harmonic-producing devices and existing correction equipment condition and control strategy.

Chasing an artificially high power factor without understanding harmonics can backfire. Overcorrection can cause leading power factor and resonance issues, especially if capacitors interact with harmonic frequencies. That’s why measurement matters.

How to Fix Poor Power Factor (Properly)

The most effective approach is: measure → diagnose → correct → verify.

Step 1: Measure the True Power Factor and Power Quality

Start with accurate metering at the right points (main incomer, major feeders, key plant). You want visibility of kW, kVAr, kVA, power factor and ideally harmonics and demand trends.

Step 2: Identify the Drivers

Is the issue primarily inductive load? Or is “true” power factor being dragged down by distortion? Do problems occur at certain times (such as overnight light loading or when a chiller plant cycles)? Are capacitor banks switching correctly?

Step 3: Apply the Right Correction Method

Common solutions include capacitor banks (fixed or automatic), which supply reactive power locally so the network supplies less kVAr. Detuned capacitor systems are designed to reduce resonance risk where harmonics exist. Active harmonic filters address distortion and can also help with reactive compensation in some setups.

Operational improvements include right-sizing motors, maintaining mechanical systems, optimising variable speed drive control and avoiding lightly loaded transformers where practical.

Step 4: Verify Results and Keep Monitoring

Power factor is not “set and forget.” Loads change, plant gets upgraded and seasonal operations shift. Continuous monitoring helps you hold gains and spot emerging issues early.

How SATEC Provides the Metering Solution

Improvement starts with knowing exactly what’s happening in your electrical system and that requires reliable, accurate metering. SATEC’s metering and power quality monitoring solutions are designed to give facilities the visibility they need to diagnose poor power factor, validate corrective actions and maintain performance over time.

Here’s how SATEC supports a measurement-led approach. SATEC meters provide detailed electrical parameters that help you understand not only your power factor but the underlying contributors to inefficiency. By tracking real power (kW), reactive power (kVAr), apparent power (kVA) and demand trends, you can see when and where power factor issues occur – whether they’re tied to a particular plant item, operating mode or time of day.

For sites where harmonics may be influencing “true” power factor, SATEC’s power quality monitoring capabilities help reveal waveform distortion and related indicators. That matters because correction strategies differ: a site dominated by inductive loads may benefit from capacitor-based correction, while a site with high distortion may need a harmonics-aware approach to avoid resonance and equipment stress.

SATEC’s compact energy metering options are also well suited to retrofit environments where switchboard space is limited, helping you add monitoring without major rework. Since metering is only useful if it leads to action, SATEC’s solutions are built to support ongoing energy and electrical performance management, including identification of abnormal operating patterns and verification of improvements after corrective works.

In short: if you want to lift power factor and keep it there, SATEC provides the energy metering foundation that makes the rest of the project practical and provable.

Power Factor: A Small Number With Big Consequences

Power factor is easy to ignore because it isn’t something you can see or hear. But it has a direct relationship to current, losses, equipment loading and operating cost. The good news is that poor power factor is usually fixable and often one of the more straightforward efficiency wins in a facility.

Start with the data. Measure properly, understand the drivers (including harmonics), apply the right correction strategy and keep monitoring. When you treat power factor as an ongoing performance metric rather than a one-off project, you’ll typically see improvements not just in bills but in reliability and usable electrical capacity too.

Contact our team to discuss your power quality metering needs.

FAQs - Poor Power Factor: What It Is, Why It Matters, and How to Fix It

What causes poor power factor in a facility?

Poor power factor is commonly caused by inductive loads like motors, transformers and HVAC plant, especially when operating at partial load. It can also be worsened by harmonics from VSDs, UPS systems and other power electronics.

Does poor power factor increase my electricity bill?

It can, either through direct utility penalties for reactive power or indirectly by increasing current, losses and demand-related costs. Even without penalties, it can reduce available capacity and contribute to inefficiencies.

What is a good power factor target for commercial and industrial sites?

Many sites aim for 0.9–0.95 or higher but the right target depends on your tariff, load profile and harmonic levels. Overcorrection can cause issues, so it’s best set based on measured site conditions.

How do I know if harmonics are affecting my power factor?

If your energy meter shows acceptable power factor but you still see high currents, overheating or capacitor problems, harmonics may be a factor. Power quality monitoring can confirm distortion and guide the right correction approach.