Every SATEC meter includes a Programmable Logic Controller (PLC). The PLC can be used for various applications such as: Substation Automation, Demand Side Participation, Demand Response, Load Control, and a variety of specialist requirements.

A new programming tool allows configuration of the setpoint logic in accordance to IEC 61131 (formerly IEC 1131).

It is an IEC standard for programmable controllers and makes the task of setting easier, by using graphical flowcharts that are common to all devices.

IEC 61131 is an international standard for programmable logic controllers, first published in December 1993 by the IEC. The current (third) edition was published in February 2013.

Part 3 of IEC 61131 deals with basic software architecture and programming languages of the control program within the PLC integrated within SATEC metering hardware.

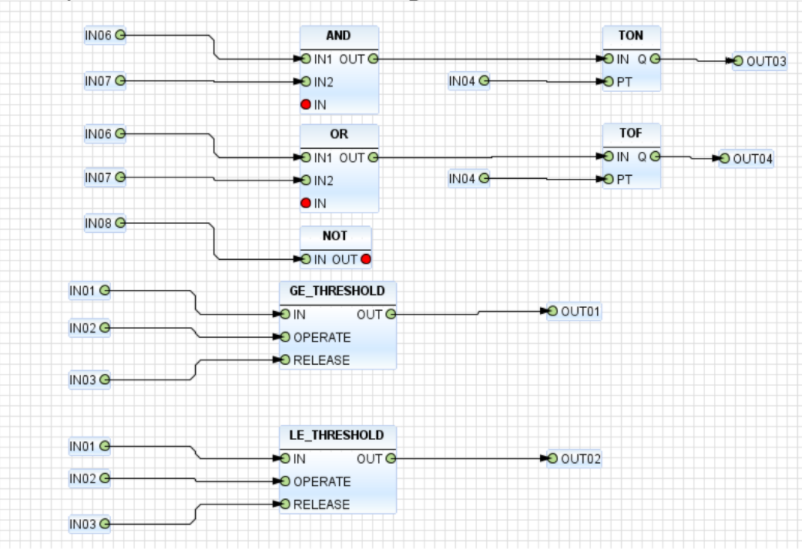

Function Block Diagram example:

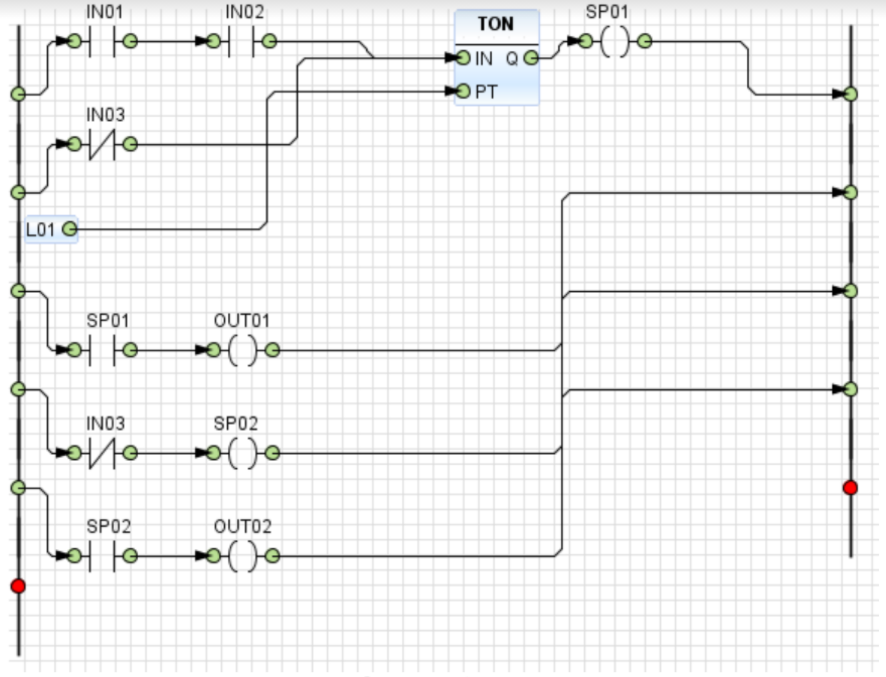

Ladder Diagram programming example:

SATEC developed special software enabling to program the logic of the SATEC eXpertMeter PM180 and new Pro Family according to the IEC 61131 standard.

Use of Ladder Logic and Function Block Diagram programming allows for automation engineers and substation engineers to collaborate effectively with limited training. Various metering manufacturers utilise custom proprietary programming languages, that is, the smart-metering that allows for this complex embedded logic functionality.

Advantage of utilising this ‘distributed logic’ concept in downstream devices improves throughput for control systems. Systems that benefit are PLC, Supervisory Control and Data Acquisition (SCADA) and Building Management Systems (BMS), as well as many other control systems requiring fast and efficient outcomes of their logic controllers. This Distributed Logic concepts improve bandwidth and the overall burden on microprocessors and ultimately productivity.

This software supports two languages:

- Ladder diagram (LD)

- Function block diagram (FBD)