In food and beverage production, power is far more than a utility bill. It directly affects product quality, uptime, safety and profit margins. Nearly every critical process depends on stable electrical supply, from refrigeration and pasteurisation to packaging lines and clean-in-place systems. The challenge is that F&B sites tend to be electrically demanding, with numerous motors and drives, frequent start-stop cycles, harsh washdown environments and round-the-clock operations.

Power monitoring provides the solution. When you can see what your electrical system is doing in real time, by line, by machine and by shift, you can reduce avoidable downtime, protect sensitive equipment and make energy decisions based on facts rather than assumptions.

Why Power Monitoring Matters in Food and Beverage

Food and beverage facilities often operate with slim margins and high customer expectations. A brief interruption or hidden electrical issue can cascade quickly into temperature excursions, rejected batches, lost production hours and costly emergency call-outs.

Power monitoring gives engineering teams and facility managers the visibility to stay ahead of issues rather than simply reacting to them. At its best, power monitoring helps you answer practical questions such as:

- Which lines are drawing unusual current during changeovers?

- Are power quality events causing nuisance trips on critical assets?

- How does energy consumption vary between shifts, recipes or SKUs?

- Are compressors and chillers operating efficiently or cycling excessively?

- What’s the true cost per batch or per pallet when energy is included?

High-Risk Areas for Electrical Issues in Food & Beverage Sites

Every site differs but several areas consistently emerge as hot spots for power-related problems in food and beverage operations.

Refrigeration and cold storage systems

Refrigeration and cold storage systems require absolute reliability. Compressors, condenser fans, evaporators and defrost cycles create highly variable electrical loads.

Without monitoring, small changes like a failing motor, incorrect defrost schedule or dirty condenser can quietly increase energy use and risk downtime.

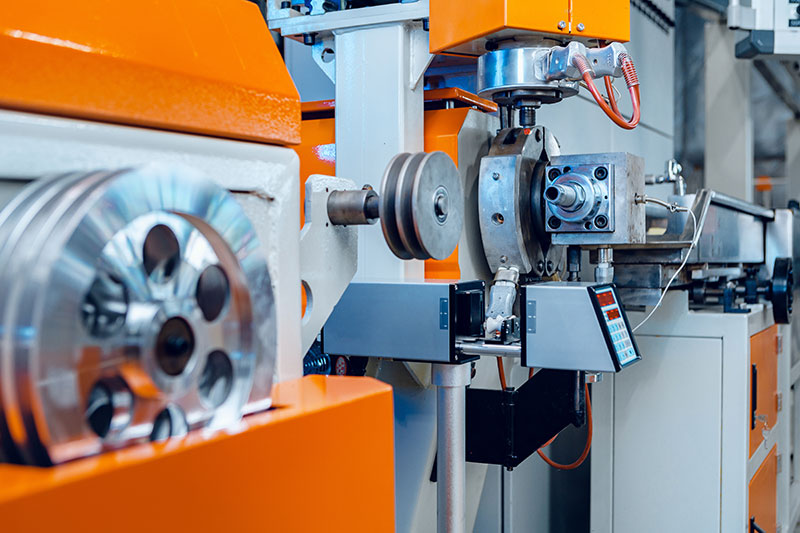

Motors, drives and variable speed systems

Motors, drives and variable speed systems power packaging lines, pumps, mixers, conveyors and blowers. Variable speed drives improve process control and efficiency but can contribute to power quality issues if not managed correctly.

Harmonics and heat buildup become concerns. Monitoring helps pinpoint where electrical stress is occurring.

Washdown environments

Washdown environments make electrical reliability harder. Moisture and cleaning chemicals lead to insulation degradation, water ingress and connection issues.

These can cause faults or intermittent behaviour that’s difficult to diagnose without data.

Compressed air systems

Compressed air systems are notoriously expensive to run. Monitoring power on compressors and related equipment can reveal leaks, poor sequencing and off-hours waste that adds up quickly.

Utility supply and distribution

Utility supply and distribution can experience voltage dips, sags and transient events from external or internal sources. When a critical line trips, you need evidence to determine root cause and make the case for corrective action, whether internally or with the supply authority.

Beyond Energy: Power Quality Monitoring and Uptime

Many organisations start monitoring purely to reduce energy spend and that’s valuable. However, the bigger win in F&B is often uptime and asset protection. Power quality monitoring can help you detect voltage sags and swells that trigger trips or damage sensitive controls.

It identifies harmonic distortion that overheats transformers, cables and motors. It reveals unbalance that shortens motor life and reduces efficiency. It highlights high demand peaks that increase network charges and strain equipment.

When you capture these events, you move from “It tripped again” to “Here’s the voltage sag at 10:42am that coincided with the line stoppage and it’s happening three times a week.” That’s the kind of information that changes maintenance planning and investment decisions.

Practical Benefits You Can Expect

Power monitoring is most effective when tied to operational outcomes. In food and beverage settings, common benefits include reduced unplanned downtime, better maintenance decisions, lower energy and demand costs, stronger internal reporting and clearer accountability across teams.

Real-time alarms and trending can highlight abnormal conditions before they become failures. That might mean identifying a motor drawing higher current than normal or spotting repeated dips that precede drive faults. Instead of time-based maintenance alone, you can add condition-based insight.

If power data shows a pump is working harder for the same output, you can investigate mechanical wear, blockage or process issues earlier. Once you can see energy use by line, area or time period, you can target the biggest opportunities. This includes adjusting start sequences, smoothing peak demand or addressing underperforming assets.

Sustainability reporting and operational KPIs become easier when the underlying measurement is solid. Power monitoring gives you credible data to track improvements and justify upgrades. When data is shared appropriately, engineering, production and finance can align around what’s really happening. That reduces guesswork and makes improvement projects easier to prioritise.

What to Monitor: A Simple Food and Beverage Checklist

If you’re starting or refining a monitoring programme, a sensible approach is to focus on the electrical points most connected to downtime, quality and cost.

- Begin with the main incoming supply for whole-site visibility, demand and power quality.

- Add cold storage and refrigeration plant.

- Include packaging lines and high-throughput production lines.

- Monitor CIP systems and major pump groups.

- Track compressed air compressors and dryers.

- Cover boiler and hot water systems where electric.

- Finally, monitor key distribution boards feeding critical loads.

From there, you can expand monitoring deeper into specific assets or lines where you need more granularity.

SATEC: The Metering Solution for Food and Beverage Power Monitoring

To make power monitoring work in the real world, especially in production environments, you need metering that’s accurate, robust and designed for both energy and power quality insights. SATEC’s metering and power monitoring products are built to support exactly that. They provide detailed visibility into electrical performance, from the main supply down to distribution and critical loads.

For food and beverage facilities, this means you can implement a structured metering approach that supports operational reliability, power quality visibility, energy accountability, scalable deployment and space-conscious installations. This last point is valuable in retrofit environments where switchboards are crowded and footprint matters.

SATEC’s portfolio includes solutions that align with demanding industrial sites where accuracy and resilience are essential. They help engineering teams move from reactive troubleshooting to proactive electrical management. When paired with software-driven reporting and analytics, SATEC meters become a foundation for ongoing improvement through clearer energy baselines, faster fault investigation and more confident decisions about upgrades and process changes.

If your goal is to improve uptime, protect critical assets and get control of electrical costs without disrupting operations, SATEC provides a practical pathway to implement reliable monitoring and expand it over time as your site’s needs grow.

Getting Started: A Low-Disruption Approach

A common worry is that monitoring projects will be complex or disruptive. They don’t have to be. Many F&B sites begin with a staged rollout. Meter the main incomer to establish a baseline and capture supply-level events. Add meters to refrigeration and top-critical distribution boards. Expand to packaging and high-load process areas. Use the collected data to prioritise corrective actions such as maintenance, settings, sequencing and upgrades.

The result is a monitoring programme that builds value quickly and keeps delivering as your visibility improves. Discuss your power metering needs with our team today.

FAQs - Power Monitoring for Food and Beverage

What’s the difference between energy monitoring and power quality monitoring?

Energy monitoring tracks consumption (kWh) and demand, while power quality monitoring looks at electrical conditions (like voltage sags, harmonics and unbalance) that can cause trips, faults or equipment stress.

Which areas should an Food and Beverage facility monitor first?

Start with the main incoming supply, refrigeration/cold storage, compressed air and the distribution boards feeding critical production and packaging lines.

Can power monitoring actually reduce unplanned downtime?

Yes. Trending and alarms can highlight abnormal electrical behaviour early (like rising motor current or repeated voltage dips), giving maintenance teams a chance to intervene before a failure.

Why are SATEC meters a good fit for food and beverage sites?

SATEC meters support detailed visibility for both energy performance and electrical conditions and they’re well-suited to scalable rollouts in industrial environments where reliability and space constraints matter.