Wide Area Monitoring Systems (WAMS) are designed to do one thing exceptionally well. They help operators understand the grid as a single, moving machine rather than a collection of isolated substations. That’s harder than it sounds. Power systems are dynamic and the most important clues often show up as tiny changes in phase angle, frequency and voltage. These ripple across long distances in fractions of a second.

This is where PMUs for WAMS come in. Phasor Measurement Units (PMUs) provide time-synchronised measurements of electrical quantities across geographically dispersed points on the network. When those measurements are aligned to a common clock, they become “synchrophasors”. This creates a shared language the grid can use to describe its own behaviour in real time. Timing accuracy is not a detail in this story. It is the foundation.

What Is a PMU and What Makes It Different?

A PMU is a device that measures voltage and current waveforms and converts them into phasors. These are mathematical representations that capture magnitude and phase angle. Traditional monitoring systems like SCADA can report values every few seconds. Often they do this without consistent time alignment across sites. That approach works for many operational tasks, yet it can miss fast, system-wide dynamics.

PMUs are built specifically for capturing those dynamics. They measure many times per second and stamp each measurement with a precise time reference. This is usually derived from Global Navigation Satellite System (GNSS), such as GPS. That time-stamp allows data from multiple substations, generators and network nodes to be compared directly. This works even when they are hundreds of kilometres apart.

In practical terms, PMUs for WAMS give operators a “wide-angle lens” on the power system. Instead of inferring events after the fact, WAMS can observe and interpret the grid as changes unfold.

Synchrophasors: The Real Deliverable Inside a WAMS

The word “synchrophasor” sounds technical, yet the concept is straightforward. It’s a phasor measurement that is synchronised to a common time source. The “sync” part is what transforms local measurements into a system-wide picture.

A synchrophasor stream typically includes voltage magnitude and angle, current magnitude and angle, system frequency and rate of change of frequency (RoCoF) plus quality flags and status indicators.

When multiple PMUs produce synchrophasors with aligned timestamps, a WAMS can plot phase angle differences across regions. It can detect oscillations, observe frequency behaviour during contingencies and support faster situational awareness. Without synchronisation, those same measurements become difficult to interpret. They can lead to incorrect conclusions about what is happening on the network.

Why Timing Accuracy Is Everything (and What Goes Wrong When It Isn't)

WAMS analytics depend on comparing measurements across sites. That comparison is only valid if the timestamps are accurate and consistent. Even small timing errors can translate into meaningful angle errors. These affect the very insights WAMS is supposed to deliver.

Here’s why. Phasor angles are tied to the waveform’s position in time. If one PMU is “late” or “early” relative to the reference clock, its calculated angle is shifted. Across a wide-area system, those shifts can make it look like power is flowing differently than it really is. They can suggest that oscillations are present when they aren’t.

Timing issues can show up in several ways:

False angle separation or masked instability. Angle differences between regions can indicate stress, congestion or separation risk. Timing offsets can exaggerate or hide those differences. This reduces confidence in the display.

Mis-detection of oscillations. Inter-area oscillations are subtle and fast. WAMS tools often look at phase angle and frequency patterns across multiple PMUs. Timing jitter or drift can distort the patterns and reduce detection reliability.

Incorrect event sequence reconstruction. One of WAMS’s strengths is helping teams understand “what happened first”. Timing errors scramble that timeline. This makes root cause analysis slower and less certain.

Reduced trust from operators. Operators adopt tools that consistently reflect reality. Data that occasionally “looks wrong” tends to get ignored in the moments it matters most.

Where Timing Comes From: GNSS, Grandmasters and Discipline

Most PMUs use GNSS receivers to lock onto an accurate time source and produce timestamps aligned to UTC. In substation environments, GNSS is often paired with time distribution methods such as IRIG-B or IEEE 1588 Precision Time Protocol (PTP). The choice depends on architecture and requirements.

A strong timing design typically includes a reliable primary time source (often GNSS), robust time distribution to IEDs and PMUs, monitoring of time quality, holdover and drift plus cyber and physical security around time inputs.

Time “discipline” matters as much as the source itself. Devices need to maintain accuracy during disturbances, signal loss or switching events. Holdover capability helps a PMU maintain stable timing when GNSS is interrupted. This can be essential in harsh environments or during severe weather events.

PMUs in a WAMS Architecture: What Happens After Measurement

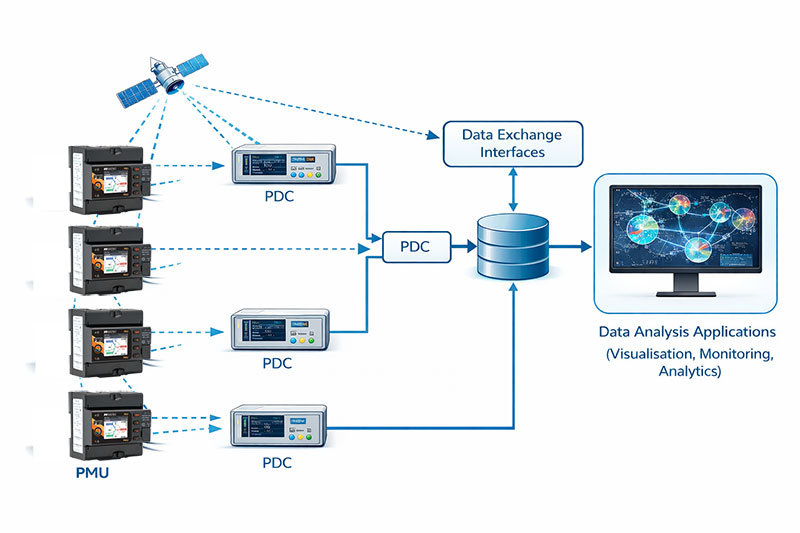

A PMU does not operate in isolation. In a typical WAMS setup, PMUs stream synchrophasor data to a Phasor Data Concentrator (PDC). The PDC aligns measurements by timestamp, filters or validates the incoming data and forwards a clean, coherent stream to applications and control rooms.

That pipeline matters because WAMS performance is not only about measurement precision. It is also about end-to-end latency and data integrity. Network design, bandwidth and the rules used by the PDC to handle missing frames or out-of-order packets all influence how useful WAMS is in real operational scenarios.

WAMS in the Australian Context: The National Electricity Market (NEM)

The Australian Energy Market Operator (AEMO) has been investing in WAMS technology to manage the National Electricity Market (NEM). The NEM operates across New South Wales, the Australian Capital Territory, Queensland, South Australia, Victoria and Tasmania. It runs on one of the world’s longest interconnected systems.

Over the past decade, the NEM has experienced a radical shift. Large synchronous generators are being replaced by distributed inverter-based resources. This shift has forced AEMO to rethink how the system is operated as new phenomena emerge that threaten power system security.

WAMS gives AEMO greater visibility over the power system than ever before. Based on high-resolution synchrophasor data being streamed in real time from across the NEM, advanced online data analytics provide deeper situational awareness. This is particularly important for maintaining system frequency within the operational range of 49.85 Hz to 50.15 Hz.

The need for instantaneous measurement of power flow throughout the NEM is critical. This is not only because of the high variability of generation. It is also because of the imbalance between consumption and generator locations. Without real-time, synchronised data, there is a likelihood of blackouts in regions that become islanded. This happens when congestion limits are reached on transmission links to the main NEM system.

What to Look For When Choosing PMUs for WAMS

Utilities and asset owners evaluating PMUs for WAMS tend to focus on a few practical performance areas.

Measurement performance and compliance. Accuracy, reporting rates and alignment with industry synchrophasor standards such as IEEE C37.118 are essential.

Timing robustness. Quality flags, holdover behaviour, monitoring and alerting around time synchronisation all matter.

Data reliability. Resilience to packet loss, graceful degradation and clear quality indicators ensure consistent performance.

Cyber posture. Secure configuration, authentication options and secure remote management practices protect the system.

Integration. Compatibility with existing substation devices, PDCs and operational workflows makes deployment smoother.

The best technical specification on paper only becomes valuable if the measurements remain trustworthy day after day. Timing accuracy plays a central role in that trust.

How SATEC Supports the Metering Layer for WAMS

WAMS succeeds when monitoring is consistent, scalable and grounded in reliable measurements. SATEC’s strength is providing the metering solution that supports advanced monitoring environments. This includes those where synchrophasor and power quality insights matter.

SATEC’s PMUs are built for demanding electrical environments where data quality is critical. They are widely used for high-accuracy electrical metering in substations and critical facilities. They support power quality monitoring to reveal disturbances, harmonics and events that affect stability and equipment performance. They enable networked measurement architectures that support centralised visibility and analysis.

On top of metering and measurement, SATEC’s Expertpower cloud software supports energy and power monitoring workflows. It brings data into a usable operational view. This helps teams move from raw measurements to actionable insight.

In WAMS programmes, organisations often need a clear separation between synchrophasor-focused monitoring and broader electrical measurement and power quality requirements. SATEC helps fill that broader measurement layer. This allows teams to standardise data capture across sites, build confidence in their monitoring stack and support a cohesive approach to visibility.

SATEC’s solutions are well-suited to Australian conditions. They support compliance with local regulatory requirements set by AEMO, the Australian Energy Regulator (AER) and the Australian Energy Market Commission (AEMC). With pattern approval, extended warranties and proven field performance, SATEC meters deliver the reliability Australian utilities demand.

Timing Accuracy as a Strategic Capability

WAMS is often discussed as a modernisation initiative. Yet it is just as much about operational confidence. Synchrophasors allow the grid to describe itself consistently across distance. PMUs make that possible, and time synchronisation makes PMUs meaningful at scale.

A well-designed WAMS does not merely collect more data. It creates a shared, time-aligned truth that operators can use to detect instability earlier, diagnose events faster and manage a more dynamic grid with greater certainty. This capability is particularly valuable in the Australian context, where the transition to renewable energy is accelerating and grid stability requires constant vigilance.

That is why PMUs for WAMS are not simply devices installed in substations. They are precision instruments in a system where timing accuracy is everything.

Talk to us about your PMU needs today.

FAQs - PMUs Explained for WAMS: The Role of Synchrophasors

What does a PMU measure in a WAMS setup?

A PMU measures voltage and current phasors, frequency and often RoCoF, then time-stamps them so the data can be compared across multiple locations in a WAMS.

Why is timing accuracy so critical for PMUs for WAMS?

Timing errors translate directly into phase angle errors, which can distort wide-area insights like oscillation detection, disturbance analysis and regional angle separation.

What is the difference between a PMU and a synchrophasor?

A PMU is the device that produces the measurements, while a synchrophasor is the time-synchronised phasor data output that a WAMS aligns and analyses.

Do PMUs replace SCADA in wide area monitoring systems?

PMUs complement SCADA by adding high-speed, time-aligned visibility into fast system dynamics, while SCADA remains valuable for broader operational status and control.