Power quality monitoring is a fundamental requirement for ensuring the stability, efficiency and reliability of modern electrical networks, especially in critical infrastructure applications such as:

- Data Centres

- Renewable energy systems (offshore wind farms, solar PV, pumped hydro)

- Water utilities (high-power pumping stations, desalination plants

- Mining operations (large HV/MV/LV VSD-driven motors for crushers, conveyors and hoists)

- Military and defence applications (naval vessels, radar systems, power propulsion)

- Heavy industrial facilities (steel mills, glass production, semiconductor fabrication)

These industries demand high-precision metering, particularly for monitoring voltage disturbances, harmonics, transient events and power factor deviations.

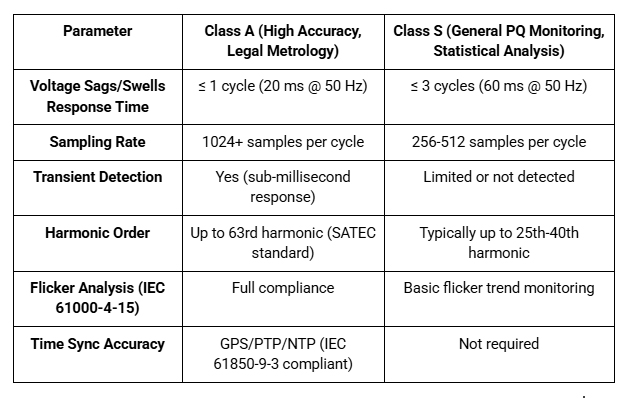

To standardise power quality measurement, the IEC 61000-4-30 standard defines the accuracy requirements for power quality meters, classifying them as either Class A (high-precision, legally traceable) or Class S (statistical monitoring).

IEC 61000-4-30: Edition 2 & Class A vs. Class S Differences

The IEC 61000-4-30 Edition 2 standard specifies measurement techniques for voltage sags, swells, harmonics, flicker and transients. It introduces enhanced sampling rates, time synchronisation and transient detection requirements, particularly for Class A meters, which must capture and timestamp power quality events accurately.

Key Differences Between Class A and Class S Meters

**SATEC Power Quality Meters surpass IEC requirements by offering harmonic measurement up to the 63rd order, ensuring precise detection of waveform distortions in high-energy environments.

Why Harmonics Matter: Industry-Specific Applications

High-order harmonics have severe impacts on power distribution efficiency, equipment lifespan and grid stability, making high-resolution measurement essential.

Application-Specific Harmonic Challenges

Offshore Wind & Solar PV

– Power electronics (e.g., inverters, rectifiers, STATCOMs) generate high-frequency harmonics affecting grid integration.

– IEC 61400-21 mandates harmonic analysis for wind turbine compliance.

Pumped Hydro & Water Utilities

– Large pump stations using MV/LV VSD-driven motors generate 5th, 7th, 11th and higher-order harmonics, leading to transformer overheating.

– IEC 61000-3-6 compliance requires stringent harmonic control.

Mining & Heavy Industry (HV/MV/LV Drive Systems)

– Large VSD-driven crushers, hoists and conveyors cause resonance issues, capacitor bank failures and voltage fluctuations.

– Harmonics above the 40th order can severely impact motor performance and power factor correction strategies.

Naval & Defence Applications

– Military ships, submarines and aircraft carriers require high-purity power to avoid interference with advanced radar, communications and propulsion systems.

– MIL-STD-1399 governs power quality standards for onboard systems.

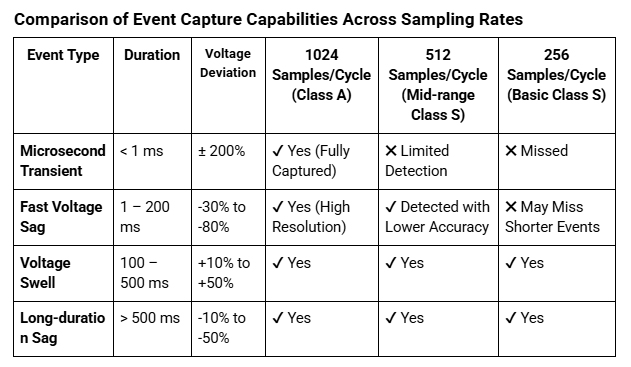

CBEMA Curve & Event Capture: The Impact of Sampling Rate

The CBEMA (Computer Business Equipment Manufacturers Association) curve is a widely recognised industry guideline that classifies power disturbances based on duration and voltage deviation.

Meters with 1024+ samples per cycle (Class A) ensure detection of fast transient events, while lower-sampling meters (Class S with 256-512 samples per cycle) often miss critical sub-cycle disturbances.

Why This Matters:

- In wind farms, solar PV, and pumped hydro, fast voltage fluctuations occur during sudden grid disconnections.

- In industrial VSD-driven motors, short-duration transients cause equipment failure and trip protections.

- In military and naval vessels, power electronics-induced microsecond transients can interfere with radar and communication systems.

Choosing the Right Meter for Your Application

Selecting the right power quality meter depends on measurement accuracy, transient capture capability and harmonic analysis range.

- Class A meters are essential for renewable energy compliance, military-grade power quality, high-resolution transient detection and legal metrology applications.

- Class S meters are suitable for general long-term power quality surveys but lack the precision required for high-energy industrial systems, wind/solar grid integration and critical infrastructure.

Why Choose SATEC?

- Harmonic analysis up to the 63rd order

- 1024 samples per cycle for transient detection

- IEC 61000-4-30 Edition 2 Class A & Class S compliance

- IEC 61850 integration for SCADA & substation automation

- Synchrophasor (PMU) support for renewables & grid stability

For industries requiring precision power quality monitoring, SATEC’s Class A and Class S meters ensure compliance, minimise downtime and provide accurate event capture for mission-critical applications.

Contact SATEC today for expert consultation on power quality solutions.