Power quality events pose constant challenges for Australian industrial facilities. Voltage sags, swells and transients can disrupt operations and damage sensitive equipment.

The Computer and Business Equipment Manufacturers Association (CBEMA) curve and its successor, the Information Technology Industry Council (ITIC) curve, provide standardised frameworks for classifying power quality disturbances.

Understanding these classification systems enables facility managers to assess power reliability and implement targeted mitigation strategies. ITIC curve specifications offer precise voltage tolerance thresholds that help organisations evaluate their power infrastructure against industry-accepted standards.

Understanding CBEMA and ITIC Curve Fundamentals

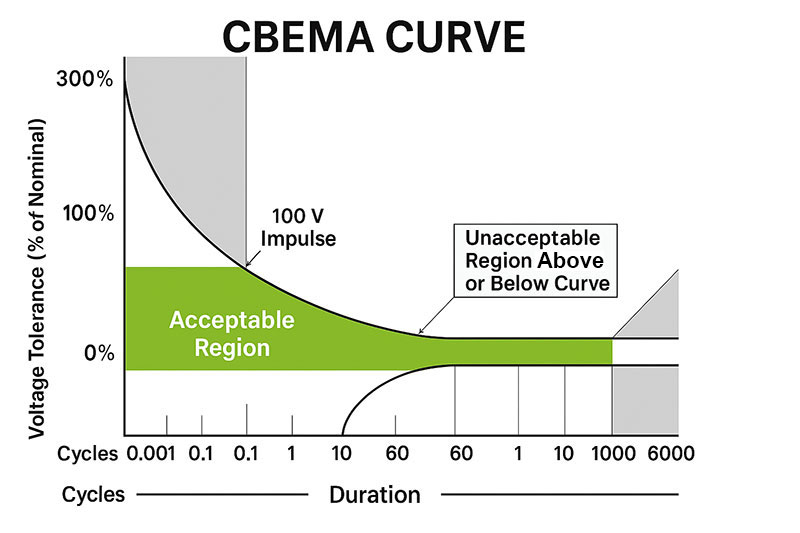

The CBEMA curve originated in 1977 to address power quality concerns affecting business equipment. Its successor, the ITIC curve, refined voltage tolerance limits for modern IT equipment. These curves plot voltage magnitude against duration to define acceptable power quality boundaries.

The curves establish three zones: no-effect zone where equipment operates normally, no-damage zone where brief disruptions occur without permanent harm and prohibited zone where equipment damage becomes likely.

IEEE 1159 standard references these curves extensively for power quality event classification. Australian facilities should utilise these frameworks to benchmark their power systems against international best practices whilst ensuring compliance with local electrical safety regulations.

Power Quality Event Categories Under CBEMA ITIC Framework

CBEMA and ITIC curves classify power quality events into distinct categories based on voltage deviation magnitude and duration. This systematic approach enables engineers to prioritise mitigation efforts and select appropriate protective equipment.

Understanding these categories proves essential for Australian industrial facilities managing diverse electrical loads and maintaining operational continuity.

Voltage Sag Classification

Voltage sags represent the most common power quality disturbance affecting Australian industry. The ITIC curve defines voltage sags as reductions to 10-90% of nominal voltage lasting from half-cycles to several seconds. Voltage sags are critical events requiring monitoring and mitigation.

Manufacturing facilities often experience sags during motor starts, transformer energisation or network switching operations. Proper classification enables targeted solutions such as voltage regulators or uninterruptible power supplies.

Voltage Swell Parameters

Voltage swells occur when voltage rises above 110% of nominal values for durations ranging from cycles to minutes. The ITIC curve establishes upper voltage limits that sensitive IT equipment can withstand without damage.

Australian facilities can encounter swells during load rejection events or capacitor switching operations. AEMO guidelines consider voltage swells as an impact on grid stability.

Proper swell classification guides selection of surge protective devices and voltage regulation equipment to maintain equipment reliability.

Transient Event Boundaries

Transient events represent brief voltage disturbances lasting microseconds to milliseconds with amplitudes potentially exceeding 200% of nominal voltage. The ITIC curve defines specific tolerance zones for high-frequency transients affecting electronic equipment. Lightning strikes, switching operations and fault clearing events commonly generate transients in Australian electrical systems.

Implementing CBEMA ITIC classification requires sophisticated power quality monitoring equipment capable of capturing and analysing voltage events across multiple timeframes.

Modern power quality analysers integrate curve overlay functionality that compares measured events against standardised tolerance boundaries. This capability enables facility managers to assess power system performance and identify areas requiring improvement.

Power Quality Analyser Implementation

Advanced power quality meters provide real-time CBEMA ITIC curve analysis through integrated diagnostic software. These instruments capture voltage waveforms at high resolution and automatically classify events according to curve boundaries.

Class A power quality analysers offer superior accuracy for precise event characterisation. SATEC power quality meters feature programmable curve parameters allowing customisation for specific application requirements. The analysers generate comprehensive reports showing event distribution across curve zones.

This data enables engineers to quantify power system reliability and justify infrastructure investments. Australian facilities benefit from continuous monitoring that identifies recurring disturbances and validates mitigation effectiveness.

Curve Overlay Analysis Techniques

Curve overlay analysis superimposes measured power quality events onto CBEMA ITIC tolerance boundaries for visual assessment. This technique reveals patterns in voltage disturbances and identifies equipment vulnerability zones.

Engineers can correlate event clusters with operational impacts to prioritise corrective actions. Software tools enable historical trending and statistical analysis of curve violations.

The overlay method proves particularly valuable for assessing power system upgrades and evaluating protection scheme effectiveness in Australian industrial environments.

Optimising Power Reliability Through CBEMA ITIC Classification

CBEMA ITIC curve classification provides Australian industry with proven frameworks for assessing power quality performance and implementing targeted improvements. These standardised approaches enable objective evaluation of voltage disturbances and selection of appropriate mitigation technologies.

Facilities that actively monitor and classify power quality events using CBEMA ITIC curves demonstrate superior operational reliability and reduced equipment maintenance costs. Australian energy transformation initiatives increasingly recognise power quality monitoring as essential for grid modernisation and renewable energy integration.

SATEC provides industry-leading power quality analysers with integrated CBEMA ITIC curve analysis capabilities. Our meters deliver Class A accuracy for precise event characterisation and feature programmable curve parameters for application-specific requirements.

SATEC power quality analysers support real-time curve overlay analysis and comprehensive reporting functions that enable Australian facilities to optimise power reliability and demonstrate compliance with industry standards. The analysers integrate seamlessly with existing monitoring systems and provide cloud connectivity for remote access and data management.

Contact our team to discuss your power quality needs.