SATEC’s trademark direct-digital-controller within metering hardware incorporates a Programmable Logic Controller (PLC) serving a breadth of applications, defining what a ‘Smart Meter’ really is.

Why use a Programmable Logic Controller in a meter?

Days of analogue instruments are fading, as is the use of ‘pulse only electrical meters’, or to the lesser extent, real-time-meters without internal memory and an internal clock. The evolution of multi-function electrical meter sees a wide gap in technology by vendors.

A traditional Programmable Logic Controller (PLC) can perform repetitive tasks reliably at low costs. By incorporating a PLC within an electrical meter, the real understanding of ‘what a Smart-Meter’ is can finally be realised.

Traditional control systems, such as a Building Management System (BMS) or Supervisory Control and Data Acquisition (SCADA) platforms have tended to perform monitoring and control tasks for energy management applications.

The use of a PLC within a Smart-Meter is proven to improve communication bandwidth, lower processor scan-time and improve code efficiency and effectiveness by optimising throughput.

A Meter for Engineers & Automation Professionals

BMS, PLC and SCADA generally performs most metering measurement and monitoring solutions. The rise of Energy Management Systems (EMS) is improving electrical metering systems due to several factors, particularly since electrical measurements and monitoring applications can be so vast in their respective applications.

There is a significant difference between low cost metering solutions and Advanced Smart-Meters. Subsequently, there is a wide gap between how more advanced solutions can serve applications best instead of traditional low cost metering implementations.

With a Programmable Logic Controller with the meter, the concept of Distributed Logic can be realised. Localised control is possible with simple use of programming software, instructing the meter to perform a wide range of tasks usually done by traditional methods.

Examples of such applications are: Demand Response, Demand-Side-Participation billing applications, Fast-Demand-Management, Enhanced Diagnostics, Auto-Load-Shedding, Change-of-State Notifications, Pulse Counting (water, gas, thermal metering), Phase Failure/Reversal Relay, etc.

The Technical Details

Through use of the Embedded PLC, Distributed Logic can be achieved enhancing control systems by improving communications bandwidth. Instead of a traditional ‘polling’ structure, the SATEC meters can send messages to BMS or SCADA on event driven applications.

This concept can also lessen the burden on scan-time, improving code efficiency and effectiveness. SATEC’s embedded PLC operates in a single-cycle, giving applications 20ms throughput @ 50HZ. Therefore, improved monitoring of assets is assured.

Demand Response applications are served best by various approaches. First, the meter can send messages to the control system when ‘Demand Thresholds’ have been met, or a triggered parameter is observed by the meter. Another approach is for the meter to perform an operation of a relay, to isolate and operate a respective load such as a pump or fan.

Data communication efficiency is also achieved within the meters. A ‘block transfer’ of 120x communication-registers in a ‘single-scan’ significantly improves control system throughput ability. Traditionally, ‘multiple-scans’ are performed by BMS/SCADA whereby SATEC meters allow for improved communication solutions.

16-Bit Scaled Data is provided to ½ data packet transmission size. However, 32-Bit structured data can also be obtained from the meters, which is more commonly used. The key point is that SATEC meters can provide more effective, efficient and lower bandwidth communication techniques with training and awareness of such features and benefits.

The Technical Details

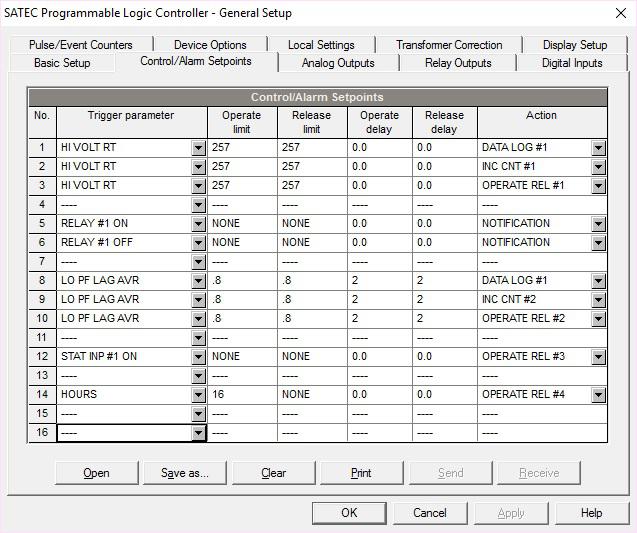

Below is an example of various applications using SATEC meters and the configurations made with the programming software.

The PLC is configurable using license free Power Analysis Software (PAS) from SATEC. The applications are divided into four (4) sections, identified by row number (1…16).

Example #1 – Row 1,2,3

This statement allows for:

IF ‘Real-Time Voltage’ is EQUAL TO ‘257’

THEN perform multiple actions:

1) Perform Data Log

2) Increment Counter #1

3) Operate Relay #1

Example #2 – Row 5,6

Example #2 – Row 5,6

This statement allows for:

IF ‘Relay #1’ is ON

THEN perform actions:

1) Send Automatic TCP/IP message to Modbus Server

IF ‘Relay #1’ is OFF

THEN perform actions:

2) Send Automatic TCP/IP message to Modbus Server

Example #3 – Row 8,9,10

Example #3 – Row 8,9,10

This statement allows for:

IF ‘Low Power Factor (lagging)’ is EQUAL TO ‘0.8’ for ‘2 seconds’

THEN perform multiple actions:

1) Perform Data Log

2) Increment Counter #2

3) Operate Relay #2

Example #4 – Row 12

Example #4 – Row 12

This statement allows for:

IF ‘Status Input/Digital Input’ is Active/True/On

THEN perform actions:

1) Operate Relay #3

Example #5 – Row 14

Example #5 – Row 14

This statement allows for:

At 16:00 hour (4pm each day)

Perform actions:

1) Operate Relay #4

In Summary

Extensive applications can be achieved using these automation & control philosophies. The true benefit of a Smart-Meter can be understood and achieved. Smarter than your average meter, the SATEC Embedded PLC is the choice for Engineers, Automation and Metering Professionals.

Contact SATEC for further information – the eXperts in Energy Management