Direct current is no longer a niche thing sitting quietly in telecom racks. It’s everywhere: solar farms, battery energy storage systems (BESS), EV chargers, DC data centres and industrial DC drives.

As these systems scale, the industry expectation is simple: if you’re billing or managing energy on DC, your metering solution needs to stand up to both Australian and international standards, where applicable for DC monitoring. Subject to the application and the project, the metering solution may be built around DC shunts – precision resistors that convert high DC currents into a small, measurable voltage drop.

SATEC’s own DC metering solutions utilise various measurement methods including shunt-based applications but how do DC shunts fit into the compliance picture? And what do the key standards, AS 62052-11, IEC 62053-41 and AS 62052-31, actually mean in practice?

First things First: What is a DC Shunt?

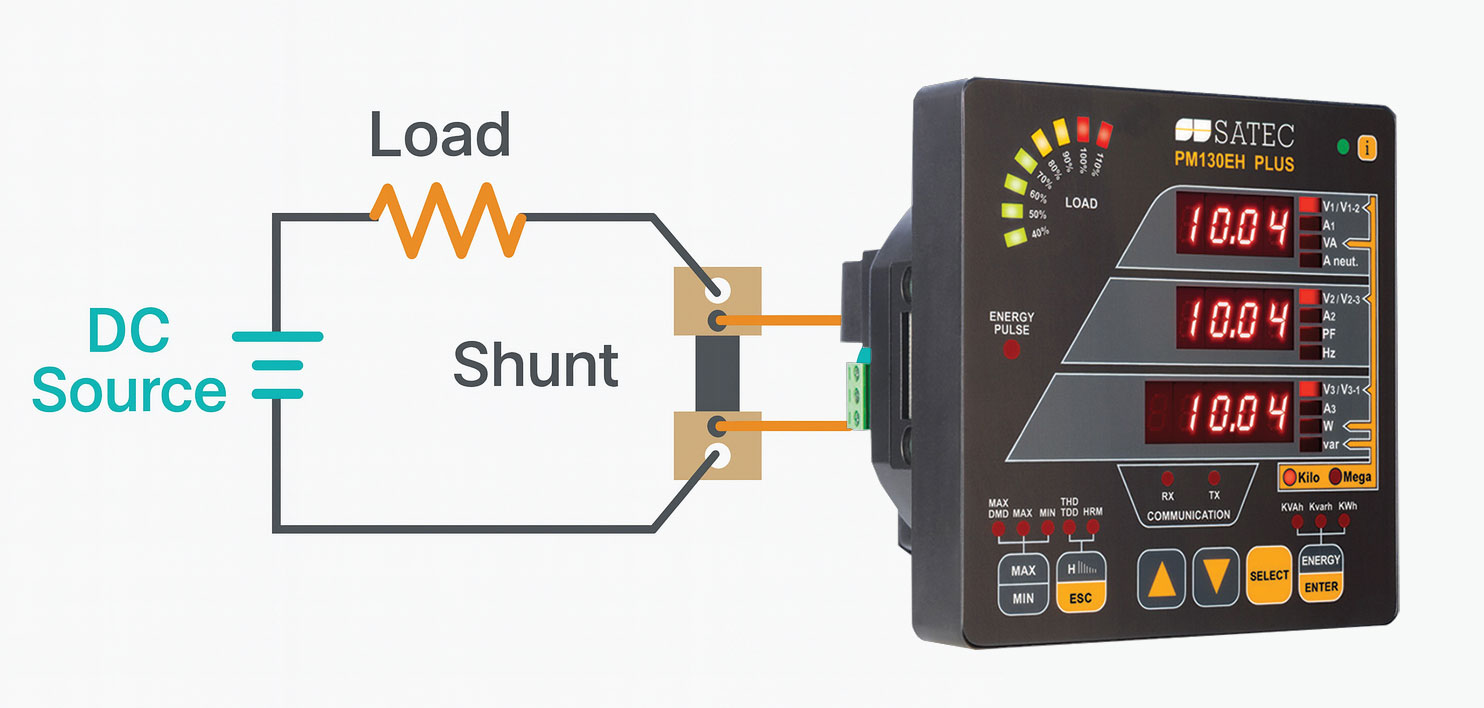

A DC shunt is a low-value, high-precision resistor installed in series with the DC circuit. Current flowing through the shunt creates a small voltage drop (for example, 50 mV, 75 mV or 100 mV at full load), which the meter measures and converts into amps, kilowatts and kilowatt-hours based on the reference DC voltage.

You’ll typically see shunt-based DC metering in:

- Telecom power systems and UPS rooms

- Battery strings and BESS racks

- DC busbars in industrial plants and data centres

- DC links in renewable and EV infrastructure

Shunts are often already installed for legacy analogue instruments or protection devices. In those cases, a modern DC meter like SATEC’s solutions can reuse the existing shunts to provide accurate digital metering, logging and communications.

The catch: once that shunt is part of a billing or compliance-critical metering chain, it falls under the same scrutiny as the meter itself. That’s where AS/IEC standards come in.

Why DC Shunt Compliance Matters

In a DC energy system, the shunt and meter together form a measurement system. If either element is poorly specified or not validated under the right conditions, you risk:

Incorrect billing: even a 1–2% systematic error can translate to large dollar amounts over time.

Disputes with tenants or customers: particularly in co-location, data centre and EV charging environments.

Safety and insulation issues: high-current DC faults are unforgiving; clearances, creepage and temperature rise must be controlled.

Regulatory exposure: more and more regulators and network operators are expecting metering to be aligned with international standards.

The AS/IEC framework takes into consideration the DC meter while the shunt forms a necessary part of the measurement system. It expects the complete DC meter (including its sensors) to be tested as a system against clearly defined performance and safety criteria.

IEC 62052-11:2020 – General Requirements and Test Conditions

Think of IEC 62052-11:2020 as the “umbrella” standard for electricity metering equipment. It defines the general requirements, tests and test conditions for both AC and DC meters. For DC metering solutions, the key themes are:

Type testing under real-world conditions

The standard sets out how meters must be tested for accuracy and stability over a specified operating range – voltage, current, temperature and time.

Influence quantities and immunity

IEC 62052-11 defines how meters must behave under electromagnetic disturbances, voltage dips, temperature swings and other environmental factors. Your DC meter (and the shunt input) should maintain system accuracy with any retention of data logged by the meter itself.

Marking and documentation

Labelling, terminal identification, ratings and installation instructions all fall under this standard. May include how the shunt connection is per the manufacturer’s guidelines.

In other words: IEC 62052-11 is where the meter proves it can do its job reliably in the environments you actually install it in.

IEC 62053-41:2021 – Particular Requirements for DC Energy Meters

If 62052-11 is the umbrella, IEC 62053-41:2021 is the DC-specific chapter. It focuses on static meters for DC energy of accuracy classes 0.5 and 1. Some practical highlights:

DC-only, static meters

The standard applies to electronic (static) watt-hour meters used to measure DC electrical energy – no rotating parts, no electromechanical mechanisms.

Accuracy classes 0.5 and 1

These classes define the maximum permissible error under reference and operating conditions. For applications like DC billing, renewable export, or sub-metering in data centres, you’re typically targeting these accuracy levels.

System voltage and configuration

IEC 62053-41 covers DC networks with two poles (one typically earthed) up to 1 500 V DC. That comfortably spans most PV arrays, BESS racks and telecom power systems now being deployed.

Type tests focused on DC behaviour

Unlike AC-oriented standards, 62053-41 includes tests tuned to DC metering: polarity-sensitive errors, load point behaviour at low DC currents, long-term stability under continuous DC load, and so on.

Where do DC shunts fit? In most cases, the shunt is treated as part of the meter’s measuring system. When you see a DC meter specified as “IEC 62053-41 compliant”, you should expect that its input chain, including shunt characteristics, has been validated in the relevant test setup.

IEC 62052-31:2024 – Product Safety Requirements

Accuracy is only half the story; safety is the other. IEC 62052-31 specifies product safety requirements and tests for electricity metering equipment designed to measure and control energy on AC and DC networks.

This standard is widely used for the mechanical and electrical safety of metering equipment generally, covering things like:

Clearances and creepage distances

Ensuring terminals, PCB tracks and sensor interfaces maintain adequate isolation under normal and fault conditions.

Protection against electric shock and fire

Including enclosure integrity, resistance to heat and fire, and the impact of abnormal operating conditions.

Mechanical robustness

Resistance to vibration, shock and temperature ranges are part of testing requirements critical for DC energy metering.

Notably, a 2024 edition of IEC 62052-31 extends safety provisions explicitly to AC and DC electricity meters, reflecting the market’s shift toward DC systems.

What This Means for DC Shunt-based Metering in Practice

So how do you translate all of this into real-world project decisions?

Treat the shunt and meter as a single measurement chain

Don’t specify them in isolation. Verify that the meter is suitable for shunt operation and that the shunt rating, burden voltage and accuracy are compatible with the meter’s input specification.

Look for IEC references in documentation—not just marketing material

For critical and billing-grade applications, ask for test reports or declarations that reference IEC 62052-11, IEC 62053-41 and relevant safety standards such as IEC 62052-31. This helps ensure you’re not installing a “DC ammeter with a kWh label”.

Pay attention to temperature and power dissipation

Shunts dissipate heat continuously at high load. Their resistance changes with temperature, which can directly impact accuracy. A compliant DC metering solution will consider this in its accuracy class and type tests, not just at a single room-temperature point.

Design the installation for safety, not just measurement

Cabling, routing, insulation, clearances, earthing and over-current protection around the shunt are all safety-critical. The best meter in the world cannot compensate for poor mechanical and electrical integration.

Think beyond the meter: data, analytics and compliance evidence

Modern DC metering platforms—like SATEC’s DC energy metering range—couple compliant hardware with data logging, communications and analytics (via platforms such as Expertpower) to provide an auditable record of energy flows and system performance.

Bringing It All Together

Compliance with IEC 62052-11, IEC 62053-41 and IEC 62052-31 isn’t just a box-ticking exercise. For DC shunt-based metering, it’s about ensuring:

- Your measurements are accurate and stable over time and environmental conditions.

- Your installation is safe under normal operation and credible fault scenarios.

- Your billing and reporting stand up to technical and commercial scrutiny.

As DC systems continue to expand across renewables, storage, EV infrastructure and data-rich environments, the bar is rising. Shunts remain a powerful, cost-effective way to measure DC current but only when they’re integrated into a metering solution that’s engineered and tested against the right AS/IEC framework.

If you’re planning or upgrading a DC installation and need to confirm whether your current or proposed DC shunt solution aligns with these standards, SATEC can help you work through the details – from meter selection through to system architecture and data integration – so that compliance, safety and accuracy all move forward together.

FAQs - DC Shunts and Compliance

Do DC shunts themselves have to be “AS/IEC certified”?

Not usually as a standalone product. Compliance is assessed on the complete metering system (meter + shunt) against AS/IEC standards like 62052-11 and 62053-41.

Which AS/IEC standard is most important for DC billing applications?

IEC 62053-41 is the key accuracy standard for DC energy meters, supported by IEC 62052-11 for general performance and IEC 62052-31 for safety.

Can I reuse existing DC shunts with a modern AS/IEC-compliant meter?

Often yes, as long as the shunt’s rating, accuracy, burden voltage and installation meet the meter’s input requirements and overall system design.

Why does safety (IEC 62052-31) matter so much for DC shunt metering?

High DC currents and fault levels can sustain dangerous arcs, so clearances, insulation and mechanical design need to meet recognised safety criteria, not just “work electrically”.