The rapid growth of solar installations, battery storage systems and DC microgrids across Australia necessitates advanced measurement technologies that can deliver revenue-grade accuracy for DC applications. Fluxgate current sensors represent a critical technology for precise DC current measurement, offering exceptional accuracy, stability and reliability compared to traditional measurement methods.

As Australian renewable energy installations continue expanding to meet ambitious clean energy targets, the demand for high-precision DC metering solutions becomes increasingly important for system optimisation, billing accuracy and regulatory compliance.

This article examines fluxgate sensor technology and its applications in Australia’s renewable energy landscape, highlighting key standards and implementation considerations for industry professionals.

Understanding Fluxgate Current Sensor Technology

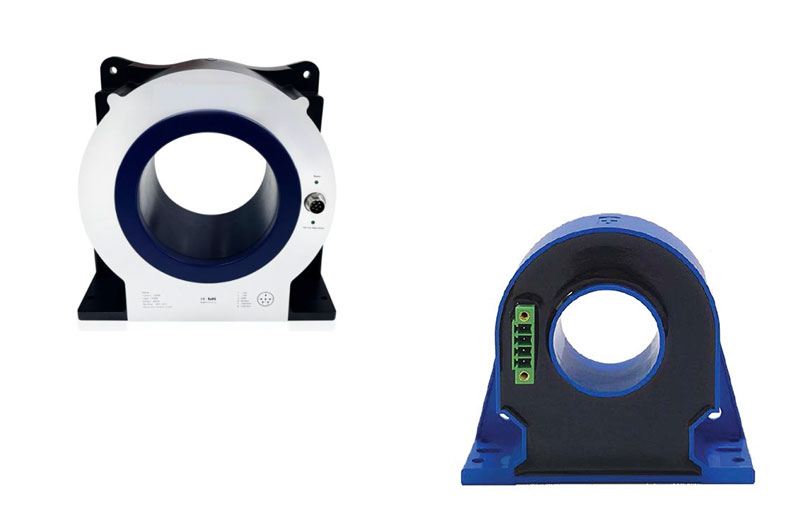

Fluxgate current sensors operate on a fundamentally different principle than conventional current transformers or DC shunt-based measurement systems. At their core, fluxgate sensors utilise a magnetically susceptible core that undergoes periodic saturation through an excitation winding.

When external DC current creates a magnetic field around this core, it causes measurable asymmetry in the core’s magnetic response. This asymmetry is detected via sophisticated electronic circuits that produce an output signal proportional to the measured current.

The key advantage of fluxgate technology lies in its ability to measure both AC and DC currents with exceptional accuracy, typically achieving 0.1% to 1.0% measurement accuracy across wide current ranges. Combined with the DC electricity meter, the total system accuracy (meter plus sensor) needs to be considered. These sensors offer excellent linearity, minimal temperature drift and outstanding immunity to external magnetic interference.

Unlike Hall effect sensors that may suffer from temperature-related drift, fluxgate sensors maintain their calibration stability across the wide temperature ranges typically experienced in Australian solar and battery installations. The zero-flux compensation method employed in many advanced fluxgate sensors further enhances accuracy by automatically compensating for core non-linearities.

Australian Standards and Regulatory Requirements for DC Metering

The integration of DC metering into Australia’s energy infrastructure requires adherence to specific standards and regulatory frameworks. While traditional energy metering has focused primarily on AC systems, the growth of DC applications has prompted the development of appropriate standards to ensure measurement accuracy and consistency.

Revenue-grade DC metering systems, including those utilising fluxgate sensors, should comply with several key factors relevant to the DC testing standards. These standards establish accuracy classes, testing methodologies and operational requirements for metering equipment used in billing and energy trading applications.

System integrators and renewable energy developers should consider these standards when selecting fluxgate current sensors and associated metering equipment for DC applications in Australia’s renewable energy sector.

AS 4777.1 - Grid Connection of Energy Systems

AS 4777.1 covers the installation requirements for grid-connected inverter systems, whilst metering standards are covered under National Measurement Institute (NMI).

For DC-side metering using fluxgate sensors, this typically means ensuring the measurement accuracy meets either Class 0.5 or Class 1.0 requirements. The DC metering standard, IEC 62053-41 in conjunction with AS/IEC 62052-11, recommends that metering equipment should operate reliably within temperature ranges from -10°C to +45°C, conditions well within the operating parameters of quality fluxgate sensors.

NMI M 6-1 Pattern Approval Specifications for Electricity Meters

The National Measurement Institute’s (NMI) Pattern Approval Specifications for electricity meters establishes the foundational requirements for metering devices used in trade applications, including renewable energy generation. While historically focused on AC metering, the specifications for DC measurement systems in Australia is yet to be ratified based on International Standards IEC 62052.41.

Fluxgate current sensors, when properly integrated into DC metering systems, can satisfy stringent accuracy requirements across wide operating current ranges.

NMI M 6-1 also specifies environmental testing requirements, including temperature variation, humidity effects and electromagnetic disturbance testing for AC measurements,

Fluxgate technology demonstrates robust and accuracy performance for DC measurements compared to alternative sensing technologies, such as DC Shunts and Hall Effect Sensors.

IEC 62053-41 - DC Energy Metering

While Australia adopts many IEC standards, the relatively new IEC 62053-41:2021 specifically addresses DC energy metering, a critical development for renewable energy applications.

This standard establishes accuracy classes and test methods specifically for DC active energy meters, providing clear guidelines for revenue-grade DC metering solutions. For high-precision applications, Class 0.5 and Class 1 meters require sensing technologies like fluxgate sensors that can maintain their accuracy across variable load conditions and throughout the meter’s operational lifetime.

The standard defines influence quantities and disturbances that metering systems must withstand, including temperature variations, self-heating effects and voltage fluctuations. IEC 62053-41:2021 also addresses immunity to external DC magnetic fields, an area where fluxgate sensors excel due to their compensation mechanisms and core design that minimises external magnetic interference, making them particularly suitable for installations near high-current DC bus systems common in utility-scale solar and battery storage facilities.

The application of fluxgate current sensors extends across multiple segments of Australia’s renewable energy infrastructure. From utility-scale solar farms to commercial battery storage systems and residential DC-coupled solar plus storage installations, these sensors provide the measurement accuracy necessary for operational efficiency and revenue protection.

Australian renewable energy developers and system integrators should consider several key factors when implementing fluxgate current sensor technology for DC metering applications. These considerations help ensure that the chosen measurement solution meets both current requirements and remains adaptable to future changes in the rapidly evolving renewable energy sector.

Implementation Considerations for Australian Renewable Applications

When implementing fluxgate current sensors in Australian renewable energy systems, several practical considerations should guide selection and installation decisions.

First, current range and scaling requirements should match the specific application, with appropriate safety margins for peak currents during transient conditions. Utility-scale solar applications and commercial installations may see current sensors with ratings from 50A up to 2000A and above.

Accuracy classification represents another critical factor, with revenue-grade applications generally requiring Class 0.5 or Class 1.0 across the operating current range.

Environmental considerations play a particularly important role in the Australian context, where installations may experience extreme temperatures. Fluxgate sensors with extended temperature specifications and appropriate IP-rated enclosures should be selected to ensure reliable operation in these conditions.

Emerging Applications in Australia's DC Metering Landscape

Australia’s renewable energy sector continues to develop innovative applications that benefit from high-accuracy DC metering using fluxgate technology. Grid-scale battery energy storage systems (BESS) represent one of the fastest-growing segments, with projects like the Victorian Big Battery and Hornsdale Power Reserve may require precise DC-side measurement for operational control and financial settlement.

These installations should consider the deployment of fluxgate sensors for DC monitoring of individual battery strings and overall system accuracy performance. DC-coupled solar plus storage systems at both commercial and residential scales also benefit from fluxgate sensor accuracy, particularly for systems participating in virtual power plant (VPP) programs where precise measurement affects financial returns.

The growing deployment of DC microgrids in remote communities and mining operations across Australia creates another application space where revenue-grade DC metering becomes essential for internal billing and operational optimisation.

Future Outlook for Fluxgate Sensor Applications in Australian Renewable Energy

As Australia continues its transition toward higher renewable energy penetration, the role of precision DC measurement using fluxgate sensor technology will become increasingly important. The growing deployment of DC-coupled systems, the emergence of DC microgrids and the integration of electric vehicle charging infrastructure all create expanded applications for high-accuracy DC current measurement.

Continued refinements in fluxgate sensor design promise even higher accuracy levels, extended temperature operating ranges, and improved integration with digital communication systems to support remote monitoring and control applications. With Australia’s renewable energy capacity projected to more than double by 2030, the demand for revenue-grade DC metering solutions will expand proportionally.

System integrators and renewable energy developers should remain attentive to evolving standards and technology improvements in this space to ensure their installations maintain compliance while benefiting from the operational insights that precision measurement enables.

SATEC provides advanced metering solutions for Australia’s renewable energy sector, including precision DC metering systems utilising fluxgate technology.

SATEC’s Expertpower software platform supports comprehensive monitoring and analysis of DC systems, with secure cloud connectivity and multiple communications options for remote installations. Our technical team offers expertise in standards compliance and system integration to ensure measurement solutions meet the specific requirements of each renewable energy application.

For more information on SATEC’s DC metering solutions for renewable energy applications, please contact our technical support team.

FAQs - Fluxgate Current Sensors

What is a fluxgate current sensor and how is it different from traditional CTs or shunts?

A fluxgate current sensor uses a magnetically susceptible core driven into saturation to measure both DC and AC currents with very high accuracy, offering better stability, linearity and immunity to external magnetic fields than conventional CTs or shunt-based systems.

Why are fluxgate current sensors important for DC metering in renewable energy systems?

They provide revenue-grade accuracy (typically 0.1–0.5%) across wide DC current ranges, which is essential for billing, performance optimisation and meeting compliance requirements in solar farms, battery storage systems and DC microgrids.

Which standards are relevant to revenue-grade DC metering with fluxgate sensors in Australia?

Key references include IEC 62053-41 for DC energy metering and AS/IEC 62052.11 specifies requirements and associated tests.

Where can fluxgate-based DC metering be used and what does SATEC offer in this space?

Fluxgate DC metering is ideal for utility-scale solar, grid-scale and commercial batteries, DC-coupled solar-plus-storage and DC microgrids; SATEC’s DC metering solutions and Expertpower software provide a complete, revenue-grade solution with advanced monitoring and compliance support for Australian projects.