Current transformers represent critical infrastructure components for electrical metering in Australian industry. These precision transformers enable measurement for load management profiling and/or for energy billing calculations and regulatory compliance.

AS 61869 standards define performance requirements for instrument transformers used in revenue applications. High accuracy current transformers ensure measurement precision whilst meeting stringent Australian regulatory frameworks.

IEC 61869 Current Transformer Standards Framework

The AS 61869 standard series establishes comprehensive requirements for instrument transformers used in electrical measurement systems.

Australian adoption of IEC standards ensures compatibility with international best practices whilst addressing local requirements. AS 61869-2 covers inductive current transformers whilst IEC 61869-10 addresses low power instrument transformers.

Revenue and load management metering applications demand strict adherence to accuracy and performance specifications. Current transformers should maintain rated performance across temperature variations and burden conditions. Proper selection criteria include primary current rating, accuracy class, cable and busbar conductor sizes along with burden capabilities need to be considered.

Australian Revenue Metering Current Transformer Applications

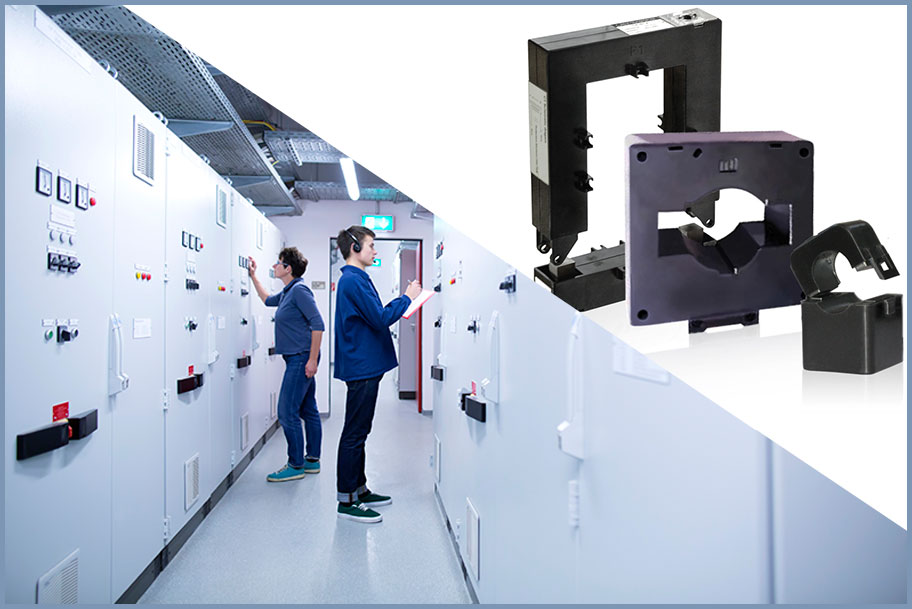

SATEC’s range of high accuracy current transformers (HACS) are used with SATEC energy metering solutions providing multiple advantages, especially in retrofit applications. In addition, SATEC provides a range of energy metering instruments enabling precise measurement of electrical energy consumption for billing purposes.

Energy metering applications require current transformers that comply with accuracy specifications outlined in Australian metering standards.

AS 61869-2: Inductive Current Transformers

AS 61869-2 specifies requirements for conventional wound current transformers used in protection and measurement applications.

Metering installations subject to its application typically employ Class 1.0, Class 0.5/Class 0.5S or Class 0.2/0.2S accuracy ratings for current transformers.

In addition, system accuracy needs to be considered based on the energy metering accuracy plus the current transformer (CT) accuracy.

These transformers provide galvanic isolation between primary circuits and secondary measurement systems. Burden specifications define the maximum load that transformers can drive whilst maintaining rated accuracy. Temperature coefficients should remain stable across operational ranges.

AS 61869-10: Low Power Current Transformers

Low power current transformers (LPCTs) offer enhanced accuracy and reduced burden requirements compared to conventional designs. These current sensors utilise technology or electronic signal conditioning to achieve precise measurements.

Current transformer applications benefit from improved linearity and extended dynamic range capabilities. LPCTs which provide current output signals provide interfacing with energy meters. Reduced secondary burden requirements enable longer cable runs without accuracy degradation.

SATEC’s High Accuracy Current Sensors (HACS) provide the perfect solution both in energy management and embedded billing applications. Furthermore, retrofit applications benefit from the use of SATEC’s HACS technology.

AS 60044.1: Australian Current Transformer Requirements

Australian Standard AS 60044.1 historically governed current transformer specifications before harmonisation with IEC 61869.

Standards Australia maintains consistency with international practices whilst addressing local regulatory requirements. Metering installations should comply with accuracy specifications that support load management and/or energy billing accuracy requirements.

Test procedures verify transformer performance under rated and non-rated conditions. Compliance documentation supports regulatory approval processes for metering installations.

Implementation of IEC 61869 current transformers requires careful consideration of installation requirements and operational parameters.

Australian industries should evaluate accuracy specifications, burden capabilities and environmental conditions when selecting various energy meters and power quality instruments. Proper installation practices ensure optimal performance and regulatory compliance.

Regular calibration and testing procedures maintain measurement accuracy throughout operational life cycles.

Accuracy Specifications for Revenue Applications

Electricity metering current transformers accuracy performance specifications are dependent on the application, such as energy billing, load management and/or power quality.

Ratings for current transformers provide performance and accuracy specifications based on load current levels and power factor. Composite error specifications account for ratio and phase angle deviations across the measurement range. Temperature compensation ensures stable accuracy performance across seasonal variations.

Calibration certificates should demonstrate compliance with stated accuracy specifications.

Installation and Commissioning Requirements

Proper installation procedures ensure optimal current transformer performance in metering applications. Primary conductor positioning should maintain uniform magnetic field distribution within the transformer core where practical.

Secondary circuit wiring should minimise burden whilst providing adequate protection against open circuits. Grounding arrangements should comply with safety standards and electromagnetic compatibility requirements.

Optimising Energy Metering Accuracy

IEC 61869 current transformers provide the foundation for accuracy system performance in conjunction with electricity meters. Proper specification and installation practices ensure compliance with regulatory requirements whilst supporting validation practices.

SATEC provides comprehensive current transformer solutions that comply with IEC 61869 standards for Australian metering applications.

Our range of current transformers delivers performance accuracy whilst maintaining stable performance across varied operating load conditions. These instruments integrate seamlessly with SATEC energy meters to provide complete measurement solutions.