eXpertpower™ energy management software solution provides comprehensive energy management, billing, demand response, power quality analysis and generator control.

Global leader in the research, development and manufacturing of energy management solutions.

With two decades of rich experience in energy management, our team has the technological expertise to deliver flexible solutions for customer applications worldwide.

Industry Experts

Technological excellence, innovation, quality and a commitment to customer service place SATEC Australia at the forefront of the energy management industry.

Quality & Reliability

We pay special attention to the quality and reliability of our products, by thorough verification at every stage of each product’s lifetime. This is supported by our 5 year warranty.

Oceania Distribution

SATEC is a global company that exports worldwide. Our Australian headquarters provides local distribution, service and support to the Oceania region.

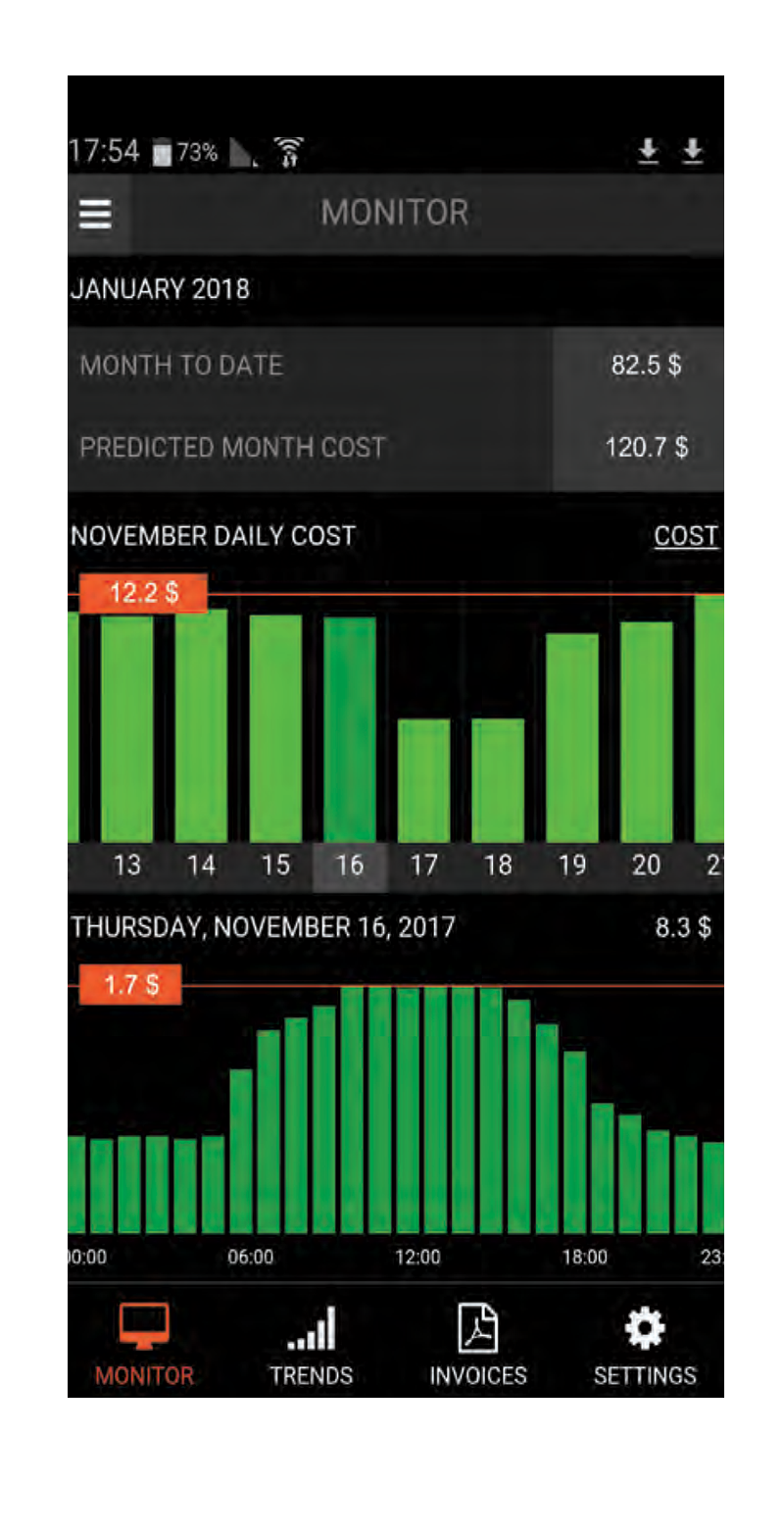

eXpertpower™ at a glance...

Data Collection

Automatic data collection from energy meters, power quality analysers and substation automation controllers.

View data in your browser

View all data in your browser – no software installation, no employee training.

Customised dashboards

Customized dashboards, single line diagrams with real time data, graphs with status indications (color, icon).

Historical information

All data is logged in the database. Trends can be monitored to identify potential problems.

Reporting

Manual, automatic or scheduled reports. Preconfigured or customized reports.

Alarms

Multi-level thresholds for complex criteria. Messaging, emails and SMS alarms.

One web-based system

Integrate all energy management, automation system and billing into one web based system.

Grow as you go

Grow as you go architecture—from single device to thousands

Advanced Smart Energy Metering

SATEC provides total energy management solutions for a broad range of applications for electricity and energy demand monitoring.

Our energy expertise covers a broad range of markets including residential, commercial, industrial, utilities and solar.

SATEC Success Stories

Our worldwide customer base consists of industrial facilities, commercial enterprises, government and public services and major power utilities.

Markets & Shopping Centres

Markets & Shopping Centres

Sub-stations

Sub-stations

Electric Vehicles

Electric Vehicles

Universities

Universities

Data Centres

Data Centres

SATEC takes pride in catering to the unique needs of our varied and world renowned customer base.

The key to our success...

Our clients are our most valuable asset

We consider excellence of products and service as a key to gaining customer loyalty and satisfaction.

Industry Experience

Our customer base consists of industrial facilities, commercial enterprises, government and public services, and major power utilities.

Continuous research and development

We set the standard by continuously developing and upgrading our products and services, to perfect our clients’ energy management systems.

The user is at the forefront of everything we do

We pay particular attention to the quality and reliability of our products. Our products are user-oriented and designed for easy installation and operation.

Energy Management & Metering News

Get in Touch With Us

We look forward to discussing your next project.

Email us by completing the form or simply pick up the phone, we are always happy to help.

SATEC (Australia) Pty Ltd

All SATEC devices comply with world-acknowledged regulations.

Our quality system is ISO9001:2015 certified and our laboratory is certified in accordance with IEC/ISO 17025.